Measurement performance

Working principle: Liquid displacement and buoyancy Measurement resolution: 2 and 9 ml Detection capacity: 3 x 107 ml for 2 ml flow cell and 13 x 107 ml for 9

BPC® Go is the next-generation gas volume and flow meter containing an in-built computer to simplify and secure low gas flow measurements. It automatically measures both wet and dry gases at laboratory scale with high precision and accuracy without the need for recalibration. Built to the highest standards of Scandinavian quality, it is simple to set up and use for online, real-time monitoring from any location.

Article no: 17-0000-01

BPC Go offers you:

NEED MORE INFORMATION?

Request a quote or book a meeting with one of our product specialists!

It’s automatic! That means no costs for labour, no expenses for expert help, and no writing results in Excel files or notebooks. A simple intuitive user interface makes setting up and monitoring any research project simple. Just fill it with water, connect to a power source, then start.

BPC Go is an excellent instrument for any application where the precise volume and flow measurements of wet and dry gases are key. It normalises gas flow rates and volume measurements at 0 ˚C and 1 standard atmosphere (atm). It is also possible to adapt the measurement to either wet or dry gases by allowing or removing measurement contributions from water vapour. Real-time temperature, pressure and humidity compensation ensure all gas volume and flow measurements are accurate.

BPC Go provides a wide detection range with high linearity up to 1500 ml/h for 2 ml flow cell and up to 6000 ml/h for 9 ml flow cell.

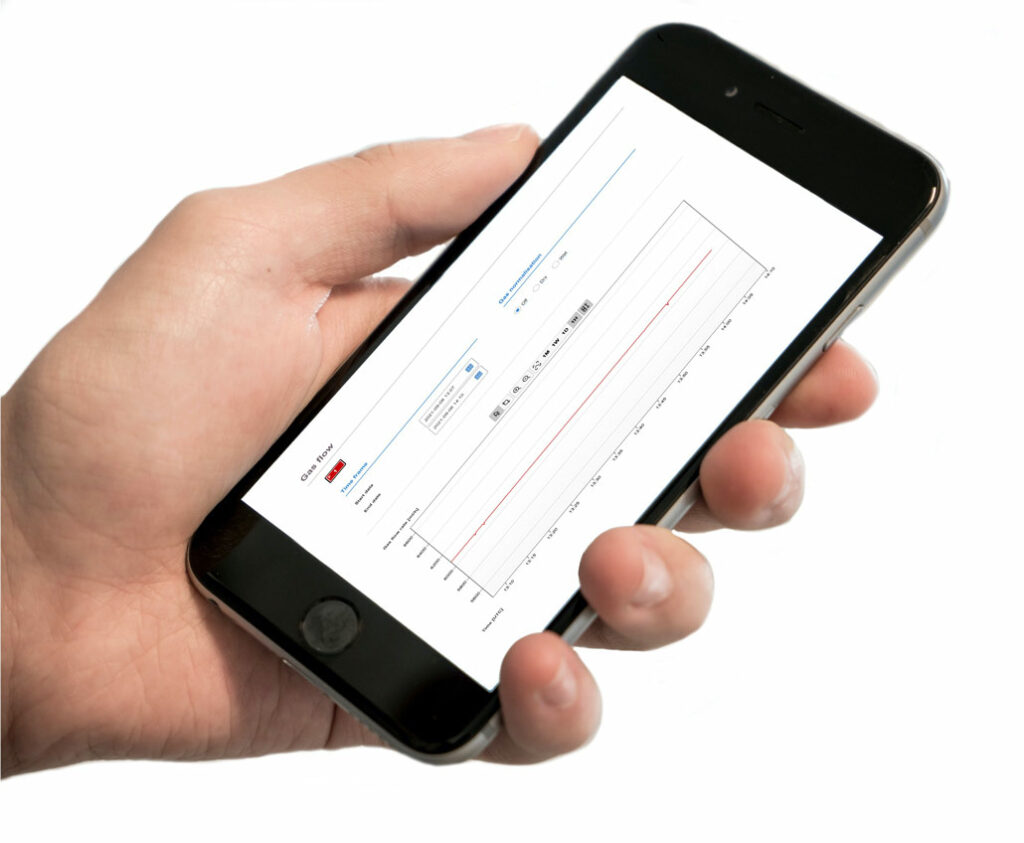

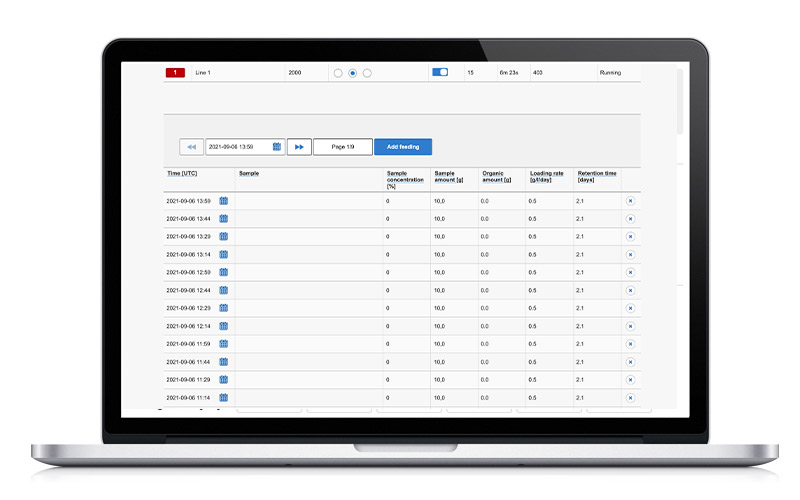

AuroraTM is BPC Instruments’ latest, custom made and revolutionary software solution for monitoring volume and gas flow. It’s slimmed down design makes it optimal for running experiments for long time periods and for storing large amount of data. Control, monitor, display and download data from your experiment using the intuitive web-based Aurora software interface.

It is easy to connect to your local network or the internet, meaning laboratories and R&D institutions around the world can monitor results from any device, including tablets and mobile phones.

Inbuilt storage and processing from an onboard embedded microcontroller enable BPC Go to store all gas volume and flow measurements. That means data won’t be lost due to a workstation or server crash, potentially saving weeks of research and development work.

BPC Go have a high flexibility for various applications. It can be operated as a stand-alone instrument for a specific application or combined with other technologies when measuring low gas volumes and flows in high precision and accuracy is needed. It also enables to run the experiments in batch or continuous modes of operations.

A modular design makes the maintenance of BPC Go easier than in any BPC Instrument product before it. The calibration-free flow cells come in two resolutions (2 and 9 ml) and can be exchanged at any point.

BPC Go comes with built in capability to control motors from BPC Instruments. Set speed, direction and on and off time to your requirements and rest assured that the content will be well mixed.

Working principle: Liquid displacement and buoyancy Measurement resolution: 2 and 9 ml Detection capacity: 3 x 107 ml for 2 ml flow cell and 13 x 107 ml for 9

Built-in sensors: Temperature, Pressure, Hall, Gyro Connections: Ethernet, Power supply, USB B, Motor control Display: OLED 2.8” 256×64 white Housing: Aluminium and plastic Power supply: 12 V DC /

BPC Go base unit: 188 x 114 x 41 mm, 366 g Flow cell unit: 138 x 102 x 45 mm, 134 g (without water) Power supply

NEED MORE INFORMATION?

Request a quote or book a meeting with one of our product specialists!