AMPTS – A Brief History by Dr. Jing Liu

It’s been 10 years since the AMPTS instrument first came onto the market and in that time, it has become our flagship product with almost a thousand units sold in over 60 countries. It’s become the first-line measuring device at numerous biogas plants as well as esteemed educational institutions around the world such as Stanford University, Lund University, University of Seoul and the University of Luxembourg.

I came up with the original idea for developing AMPTS because the operation of conventional anaerobic batch fermentation testing is very time and labour intensive, with poor data quality and quantity. Since manual operation is the main source of random errors, the precision and accuracy of analysis is largely up to the skill and experience of technicians and lab engineers. In addition, it’s just not realistic for companies to run these tests as a routine analysis as it takes up too much staff working hours.

In 2008, I came up with the idea of developing an automated instrument with a novel design of gas volume meter. It needed to fulfil the following design criteria:

1. Be a highly reliable meter that can measure gas volume at ml level per day without an overly complicated electronic and mechanical design.

2. It should be based on the volumetric measuring principle, so the measuring can be done without an over- or under-pressure condition.

3. It should be designed for wet gas allowing for the possibility of gas composition change. The moisture content, temperature and gas composition variation should not impact the measurement precision and accuracy.

4. It should be designed so that future development can accommodate a gas volume meter array in order to support multiple test lines.

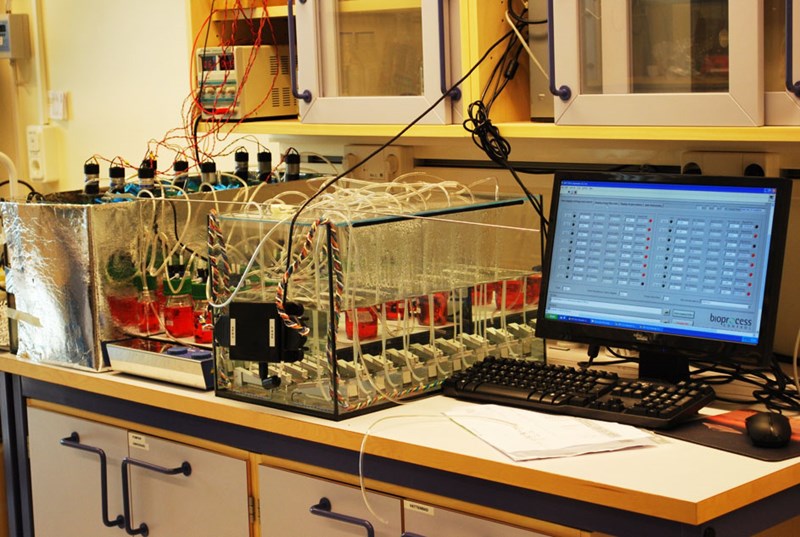

After considering several initial designs, I chose a triangular flow cell shape with a magnet detector sitting on top that flips open. I searched through a lot of different raw materials for constructing the flow cell and found them in a local home improvement store and after putting it together I began testing it in my kitchen! The single volume meter was then further developed into a volume meter array.

Around the same time, I built our first prototype, again from ready-made materials, and I developed the software needed to control the machine and store the data. After the success of these initial tests, the machine went into production.

This first commercial AMPTS model sold over 70 units from late 2009 to 2010, with turnover growing from a few million Swedish kr in 2009 to just under 10 million Swedish kr in 2010.

After the resounding success of the first model it was time to develop an improved and updated version. This new version would no longer rely on external PC-based data acquisition. It would instead use a superior network-accessible, browser-based interface. This means that users could access their data anywhere in the world using a smart device or a computer. The new version would also feature less risk of detection unit leakage and electrical wire corrosion when immersed in water. To achieve these improvements, we worked hard to develop the new product from 2010 to 2011 and in summer that year we launched AMPTS II. It had a completely new electronic and software design in the detection unit, a new embedded micro-controller and embedded web server as well as a host of other improvements. Also, the instrument’s aesthetics were in keeping with the latest industrial design.

Since the launch of AMPTS II, we have continuously updated the product with improvements to agitation, the sealing caps, the flow cells, electronic detection and the embedded micro-controller. We can confidently say that the current 2019 AMPTS II model may look very similar to the 2011 model, yet almost all critical components have been replaced and improved over the years. The performance of the current model of AMPTS II is far more reliable and is the best version so far.

Over the years, AMPTS II has become the preferred analytical instrument for conducting BMP and other anaerobic batch fermentation tests in the biogas sector. Our statistics show a continuous growth of reference scientific publications utilising AMPTS II. In 2019, we have identified over 400 English language scientific publications using data from AMPTS II and plenty more in other languages. In recent years, we have also seen an increasing number of standard and laboratory methods & protocols using AMPTS II as the standard apparatus. This includes the German VDI 4630 (2016), the CIE4485 SMA test protocol from Delft University of Technology (2012), and the sludge activity test from University of Southern Queensland (2015).

In 2017 and 2018, Bioprocess Control participated in two international inter-laboratory studies that included roughly 40 laboratories from fourteen countries. During these studies, AMPTS II was used in more than 50% of the laboratories. During the pre-conference at the IWA Anaerobic Digestion Congress in Delft 2019, AMPTS II was recognised as one of the most trustable and reliable automated instruments for BMP analysis. The precision of measurement and data calculations have been validated with highest quality and standards. In fact, the technical specification of AMPTS II has become something of a standard for running BMP tests. It’s also become a reference for several of our competitors to develop similar automated instruments.

AMPTS has been on the market since 2009, and since then its successor AMPTS II has become the de facto standard lab instrument for many biogas research groups. We at Bioprocess Control will continue to develop and improve this groundbreaking, user-friendly instrument. With close to a thousand units already sold and solid validation from institutions and technical experts under its belt, the future of AMPTS looks very bright indeed.