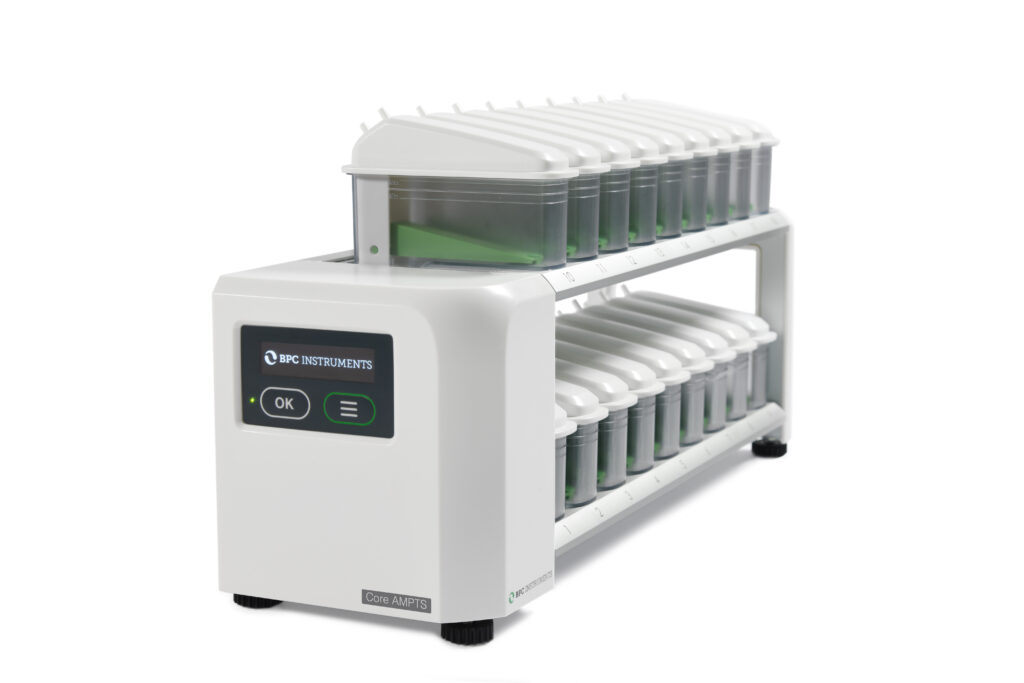

What is the AMPTS

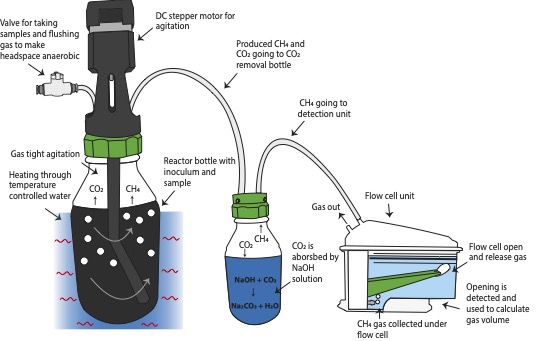

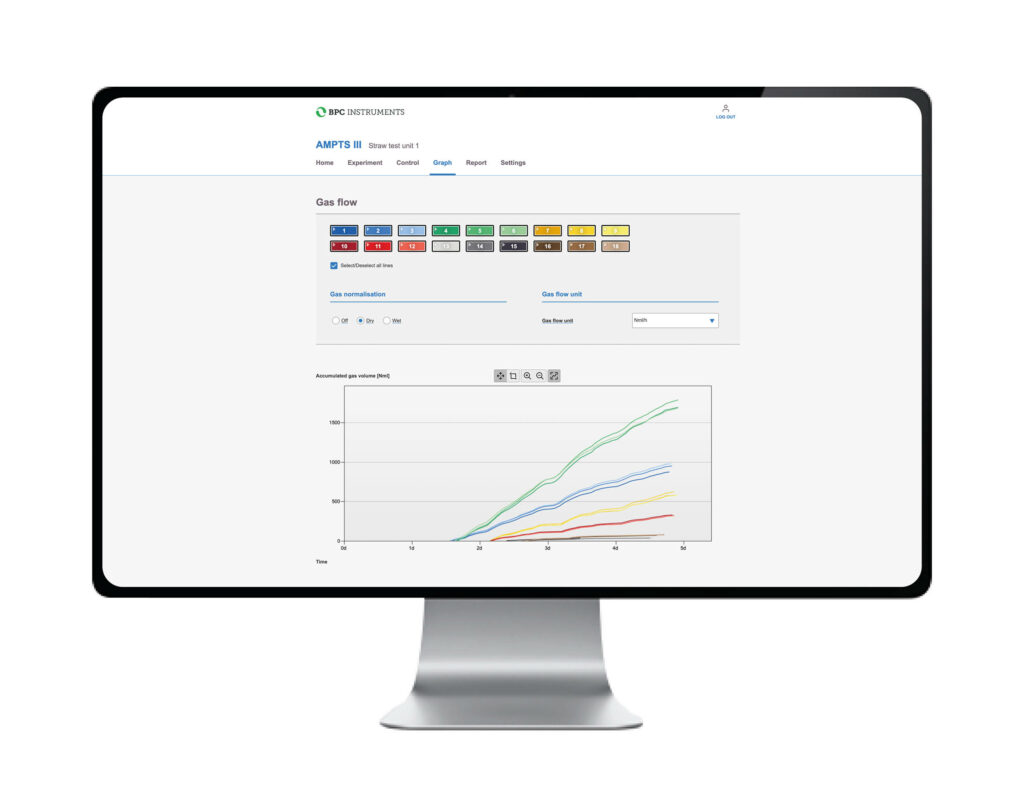

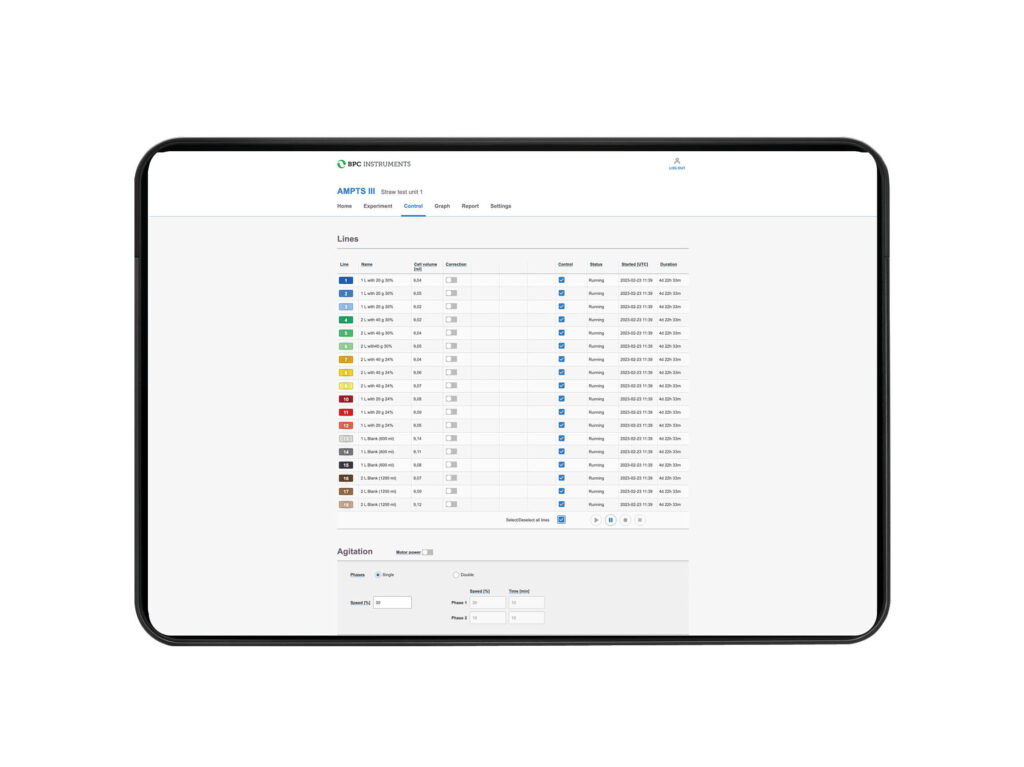

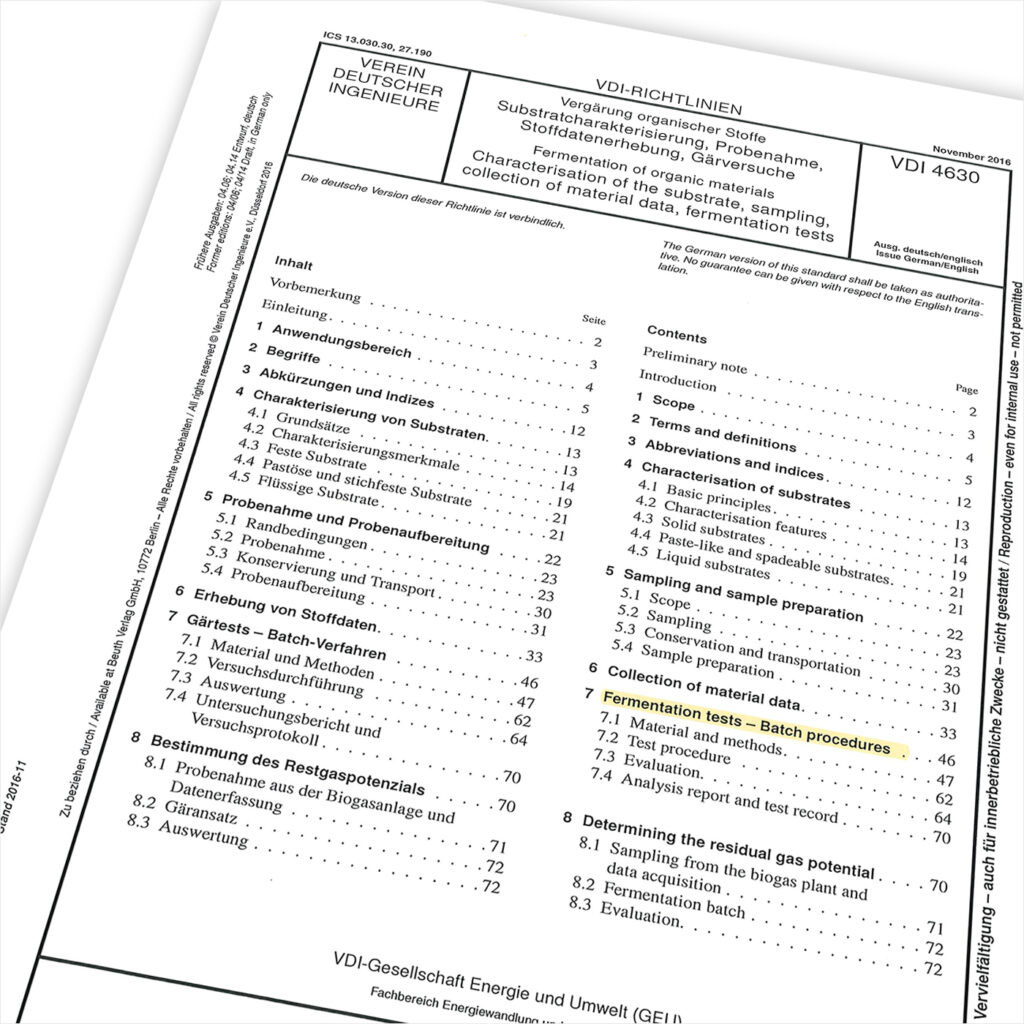

AMPTS is the analytical tool preferred by scientists and engineers for conducting anaerobic batch fermentation tests. The latest generation of AMPTS comes in two models (AMPTS III and AMPTS III Light) that house 18 or 9 test vials, respectively. AMPTS III automates and simplifies a wide range of testing, including biochemical methane potential (BMP) tests, biogas potential, anaerobic biodegradability studies, specific methanogenic activity (SMA) assays, and residual gas potential (RGP) analyses on digested slurry. With either AMPTS III model, sampling, analysis, recording and report generation are fully integrated to offer users a seamless testing experience.