For others it’s waste,

for you it’s money.

Why waste it?

Instruments for anaerobic batch and continuous fermentation tests

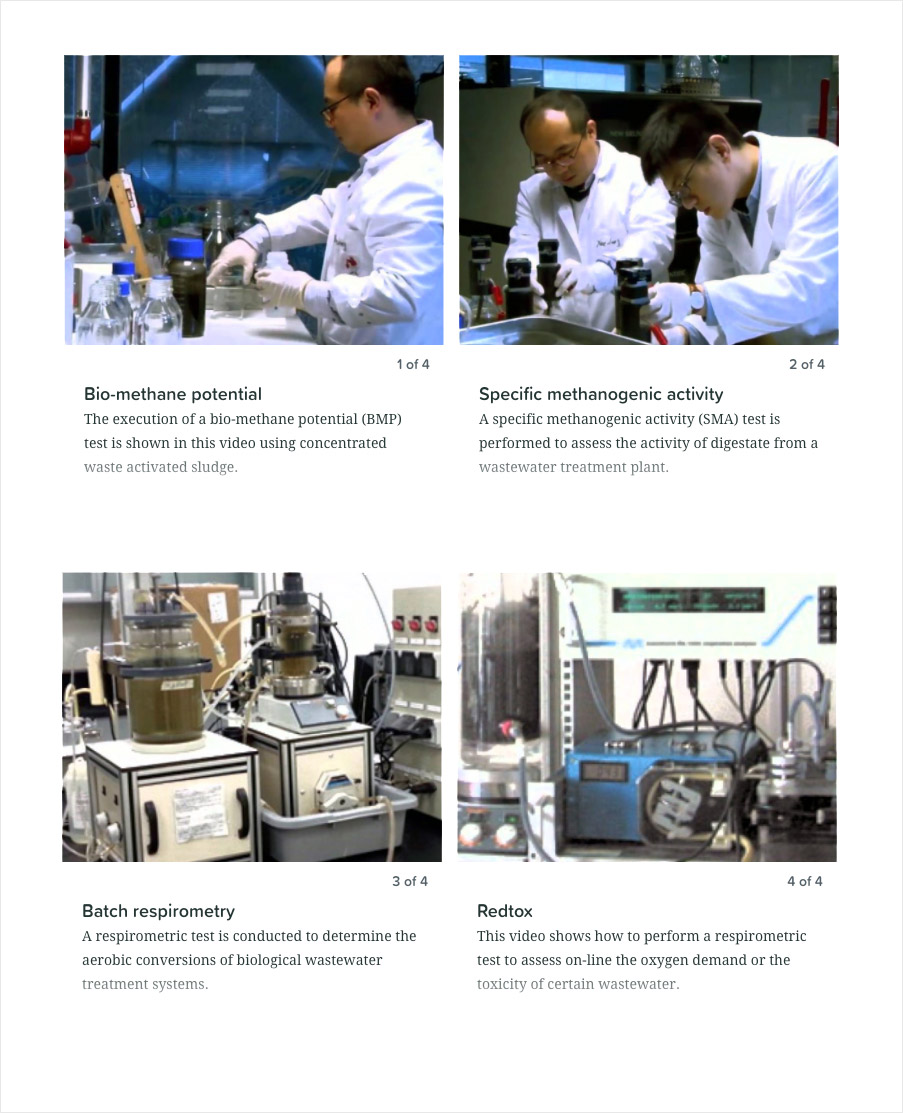

The anaerobic batch fermentation test is a well-established test system for the determination of the biogas potential and biochemical methane potential (BMP) of organic materials, specific methanogenic activity (SMA), residual gas potential (RGP) and substrate inhibition. Several standards and guideline are available for performing batch anaerobic fermentation tests, such as VDI 4630 (2016) and ISO 11734 (1995). These laboratory-based tests give a biogas or biomethane yield which can provide information regarding

- Fundamental evaluation of the possible biogas / methane yield and of the anaerobic biological degradability of organic materials

- Qualitative appraisal of the kinetics of anaerobic degradation

- Qualitative evaluation of the inhibitory effect

The AMPTS® is a well-recognized and the recommended laboratory platform according to the German norm VDI 4630 and several international laboratory protocols for conducting biochemical methane potential or biomethane potential (BMP), specific methanogenic activity (SMA) and biohydrogen potential analyses. Cited in more than 1000 peer-reviewed scientific articles in English and more in other languages and conference proceedings, the AMPTS is the preferred analytical tool of scientists and engineers for conducting a wide variety of anaerobic batch fermentation tests.

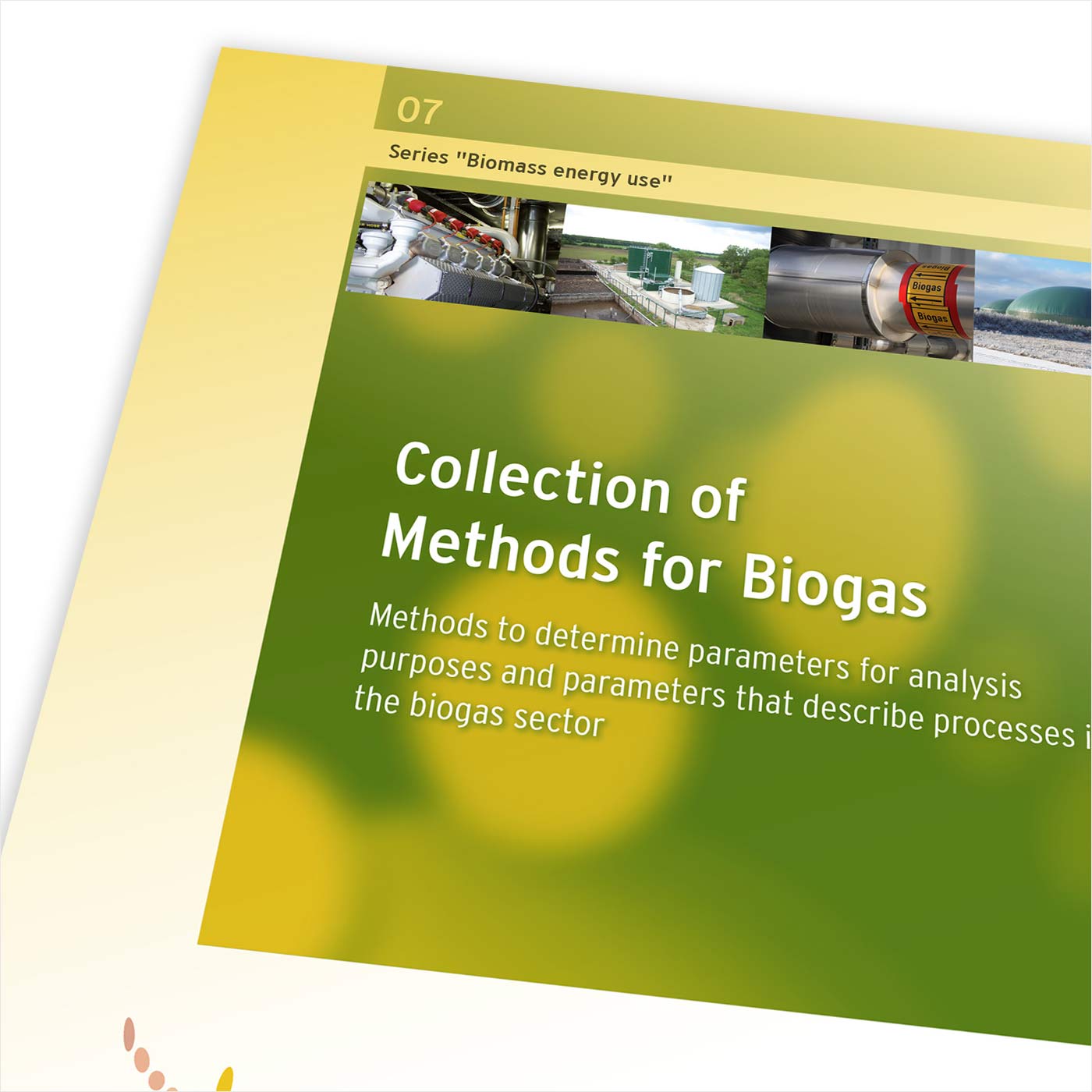

Continuous anaerobic fermentation tests are complementary to batch anaerobic fermentation tests, while allowing the user to investigate a range of other parameters. These include continuous feeding, calculating biogas yield under practical conditions due to possible negative or positive synergistic effects, evaluating the mono-fermentability of a substrate under process conditions and understanding the limits of the organic loading rate per unit volume. For process optimisation, a combination of batch tests and continuous tests should be carried out. The continuous test simulates long-term process conditions, whereas a large number of batch tests running in parallel provide results relating to the effects of relevant parameter variations. The batch test can also be used for the pre-selection of process variants for subsequent continuous trials.

Due to a broad range of process configurations and lack of standardised test procedures for continuous test, it is often not straightforward to find a standard laboratory platform and both ample time and effort for customisation is required. BPC Instruments offers BPC® Go, BPC® BioReactor Simulator and anaerobic BPC® Bioreactors in various sizes and configurations that allow you to easily set up test platforms for simulating your anaerobic digestion processes in continuous operations at both laboratory- and small pilot-scales.