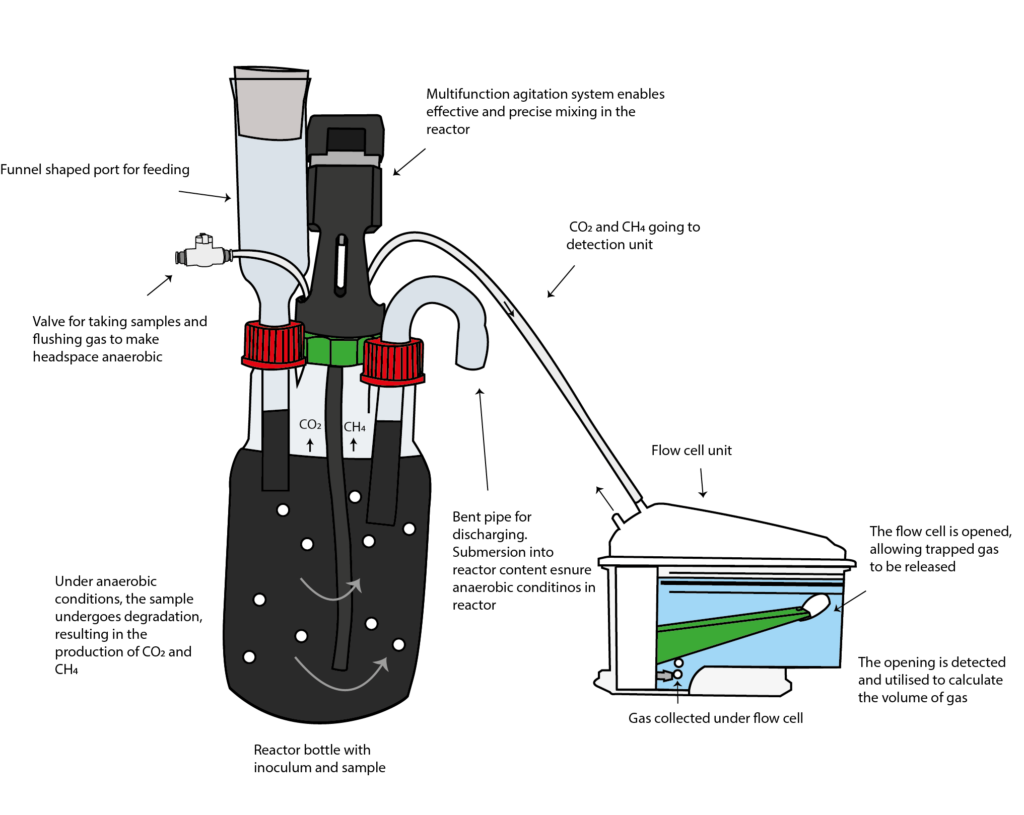

Working principle: liquid displacement and buoyancy

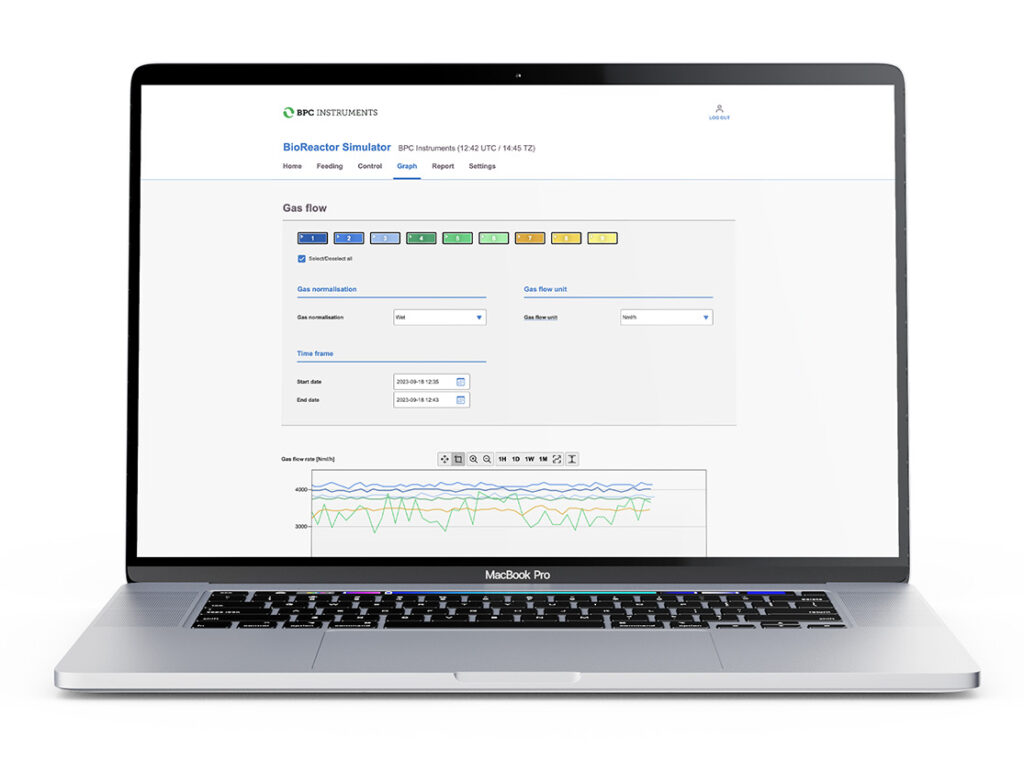

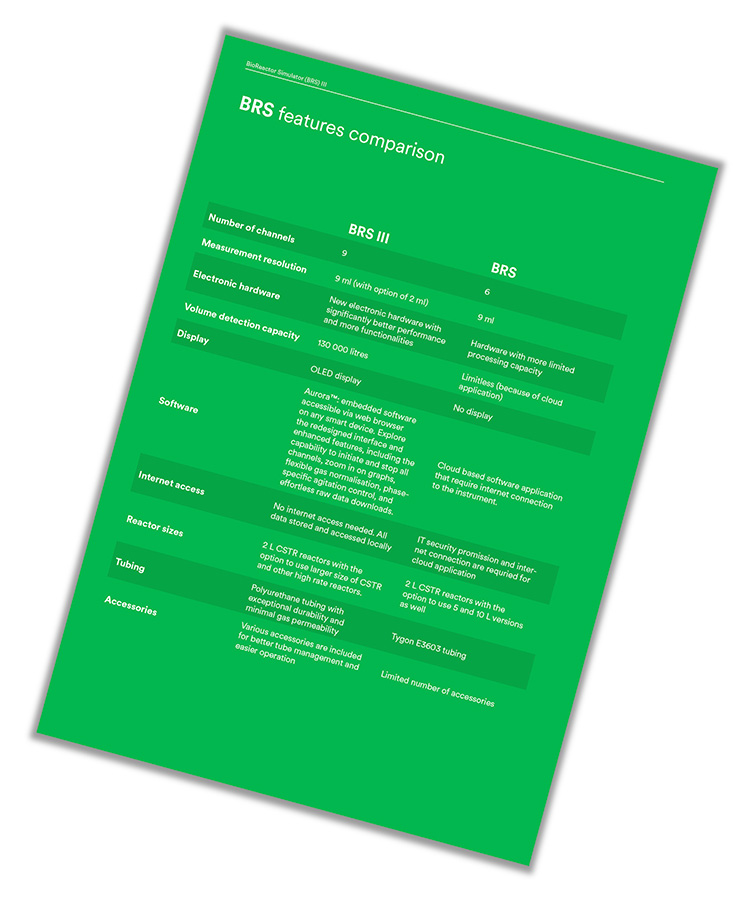

Number of flow cell units: 9

Unit dimension of unit: 55 x 19 x 17 cm

Built-in sensors: temperature, pressure, hall, accelerometer

Connections: Ethernet, power supply, USB B, motor control

Display: OLED 2.8” 256 x 64 white

Housing: Aluminium and plastic

Power supply: 12 V DC / 1.0 A with 100-240 VAC

Usage: Indoor

Measurement medium: Deionised or distilled water

Operation temperature: 0 – 50° C

Operation pressure: -50 – 50 mbar

Gas connector diameter: ID: 2.4 – 2.6 mm; OD: 4.2-4.7 mm

Recommended tubing size: ID: 4 mm; OD: 6 mm

Measuring resolution: 9 ml and 2 ml

Detection capacity: 14400 litres per channel with 9 ml flow cell and 3200 litres per channel with 2 ml flow cell

Measuring range: 1 to 6000 ml/h for 9 ml flow cell and 0.2 to 1500 ml/h

Repeatability: CV ≤ 1% for 9 ml flow cell and CV ≤ 3% for 2 ml flow cell

Gases: Non aggressive gases (e.g. CH4 , CO2, H2, N2,…)