Gas Endeavour III is an advanced laboratory instrument platform designed for precise evaluation of gas production or consumption in both batch and continuous processes. With its fully automatic operation, user-friendly interface, and high reliability, Gas Endeavour III offers exceptional ease of use. The instrument features 18 or 9 parallel channels, allowing for the simultaneous evaluation of a large number of samples.

Article no:

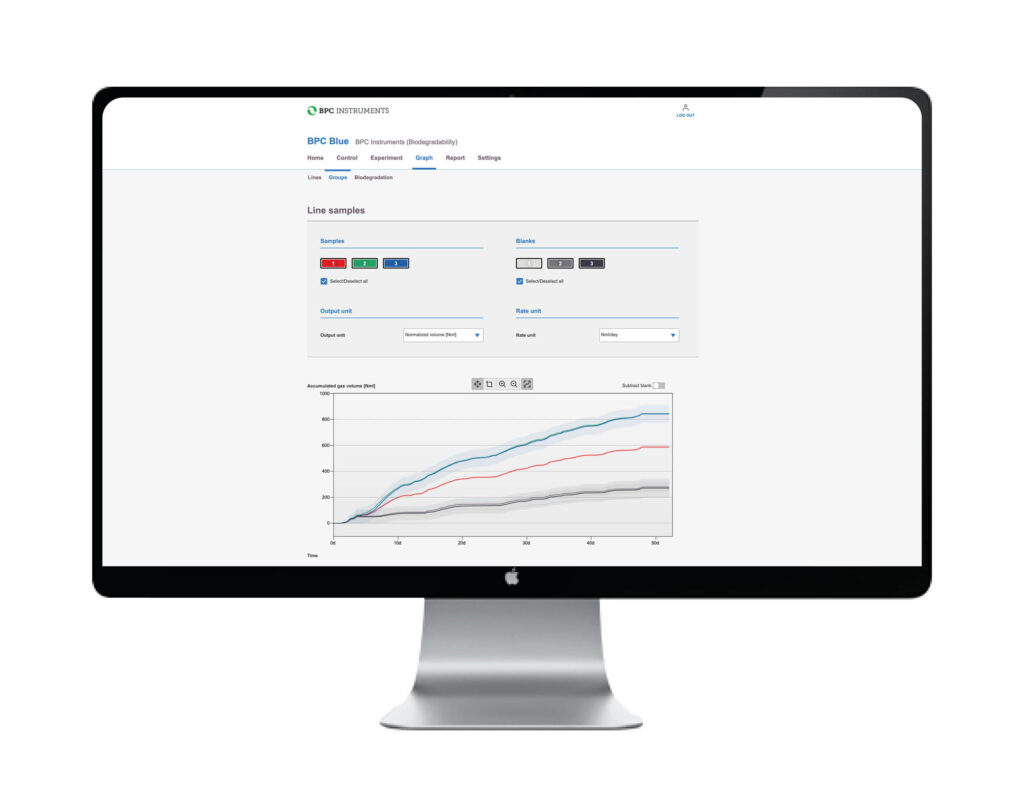

Web-based convenience: The user-friendly web-based software running on an embedded server, eliminates the need for software installation on a PC, tablet, or smartphone.

Remote access: Gas Endeavour III can be accessed remotely and locally from any device with a web browser, providing flexibility and convenience.

Automated measurement: Enjoy automatic measurement with real-time pressure, temperature and moisture compensation, ensuring accurate and reliable data acquisition.

Calibration-free operation: Gas Endeavour III operates without the need for calibration, simplifying maintenance and ensuring consistent performance.

Multiplexing potential: Take advantage of the multiplexing capability, allowing simultaneous batch analysis at different start-up times. Benefit from the flexibility to operate both batch and continuous fermentation tests effortlessly. Seamlessly switch between batch and continuous presentation, empowering you with versatile experimentation options.

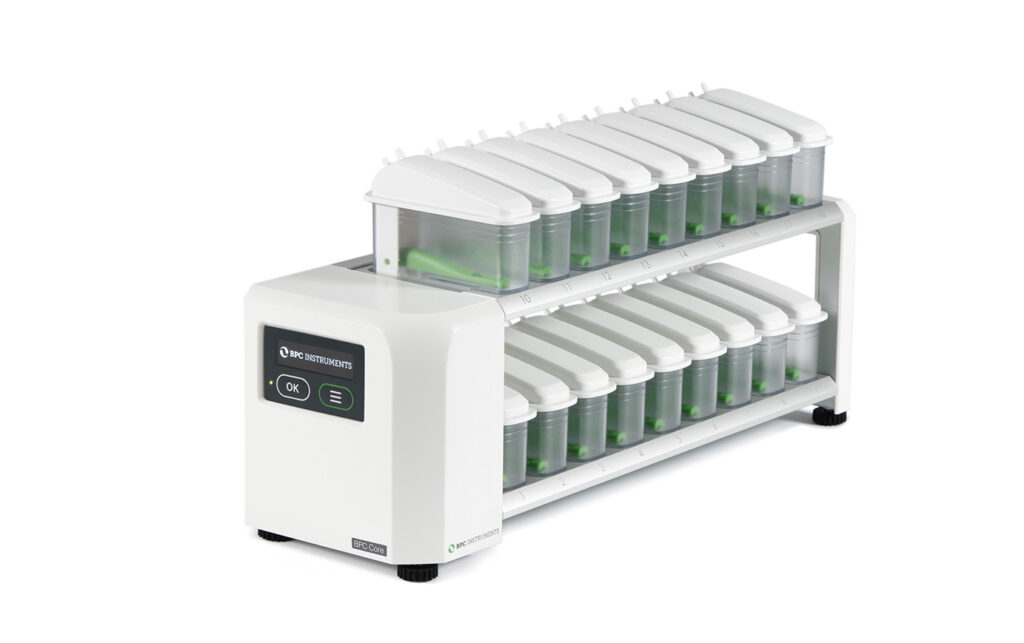

Easy maintenance: The modular design of Gas Endeavour III facilitates easy exchange, making maintenance hassle-free.

Local data storage: All data is stored locally on the instrument, eliminating the dependence on an external computer and ensuring data security.

Streamlined data processing: Export data as a spreadsheet for further analysis, featuring a uniform time axis for easy processing and interpretation.

High data storage capacity: With remarkable capacity of 7200 l of gas per channel, Gas Endeavour enables extensive data collection and analysis.

Real-time measurements: Simultaneous monitoring of multiple gas types.

Gas composition estimation: Connect in series to get real time estimation of gas composition.

Unleash powerful and reliable agitation: Experience proven multifunctional excellence

Outputs in various time intervals: Gas Endeavour generates outputs at customizable time intervals, ranging from a data point every minute to one every day, providing flexibility for your specific needs.

Flexible measurement resolutions: Switch effortlessly between 2 and 9 ml for precision and accuracy.

Versatile operation modes: Run in both batch and continuous mode.

NEED MORE INFORMATION?

Request a quote or book a meeting with one of our product specialists!

Gas Endeavour III presents two versions: a standard 18-channel edition and a compact 9-channel Light variant. It offers a total of seven configurations, including standard configurations with two flask size options, Animal Nutrient, DUO, and Max packages. Here are some of the frequently utilized configurations. For further details on system configurations, please contact our product specialist through the online inquiry form found at the bottom of the page.

This comprehensive package includes 2 L CSTR reactors with feeding and discharge sets, both in-situ and ex-situ gas absorption attachments, and gas bags for precise gas production and consumption testing. Additionally, MAX includes two BPC Core units for accurate gas monitoring before and after removing specific gas components.

A cutting-edge laboratory instrument designed to accurately measure gas volume and flow across a wide range of applications. This intelligent analytical tool is adept at measuring low gas volume and flow, ensuring precise and reliable results whenever accuracy is paramount. Its versatility makes it suitable for both research and industrial applications, including animal nutrition studies, wastewater analyses, ethanol fermentation, hydrogen production, evaluation of microbial communities, and assessing microbial communities and their activity.

Gas Endeavour III empowers researchers and industry professionals with reliable gas volume and flow measurements, enabling precise control and optimization of various processes.

Gas Endeavour revolutionizes the industry by significantly reducing labour requirements and mitigating the risk of human errors, surpassing conventional methods and competing solutions. Once experiment preparation and setup are completed within a few hours, Gas Endeavour seamlessly automates the entire testing process until its conclusion. Real-time monitoring and readily accessible reports enable effortless examination of experimental data, simplifying testing procedures like never before.

Gas Endeavour boasts robust operations and a modular design that incorporate the best elements of Scandinavian form and function, ensuring quality and reliability. With a failsafe mechanism in place, no data is lost even if the entire system goes down. Additionally, the modular design makes the maintenance a breeze as many parts can be exchanged without sending the instrument to a workshop.

Incorporating BPC Instrument’s cutting-edge gas detection unit, the Gas Endeavour introduces the remarkable capabilities of BPC Core. Distinguishing itself from other instruments, it accommodates both bath and continuous experiments, offering unparalleled versatility. Additionally, with measurement cells available in both 2 and 9 ml resolutions, switching between resolutions to meet specific requirements become effortlessly feasible.

Aurora™ is BPC Instruments’ cutting-edge software solution for its laboratory instruments, bringing your experiments to life. With its streamlined design, setting up experiment, monitoring progress, and downloading results becomes effortless. Aurora™ comes pre-installed on Gas Endeavour, eliminating the need for software licenses or installation on external computer.

Gas Endeavour is designed for convenient access from any remote location using a web browser on your preferred device. Monitor your experiment from the comfort of your office or home using your computer, tablet or smartphone. Expand the analytical capacity of Gas Endeavour effortlessly by connecting multiple instruments together with an Ethernet switch. With this feature, each Gas Endeavour can be operated as a standalone device or be connected in parallel, catering to your specific needs.

The agitation system integrated into Gas Endeavour is powered by high-quality multifunction brushless step motors. This robust system ensures the delivery of gentle, precise, and reliable agitation within a gas tight environment. Designed to excel even in challenging conditions like anaerobic fermentation processes, this agitation system has earned the trust of numerous satisfied customers worldwide.

Gas Endeavour III can be coupled with our new BPC Air incubation unit instead of a traditional thermostatic water bath. The BPC Air is an air-based incubator specifically designed to seamlessly integrate with our respirometer systems.

By combining Gas Endeavour III, you can run tests at a range of temperatures with both heating and cooling (10 – 60 oC) for long periods of time, without worrying about refilling your incubation medium.

Available for both aerobic and anaerobic configurations, BPC Air also offers lower power consumption and is a highly mobile instrument that can fit into most available laboratory areas.

NEED MORE INFORMATION?

Request a quote or book a meeting with one of our product specialists!